The purpose of drying cargo tanks is to remove humid air, which would be present during a dry docking or tank inspection. As part of the process of preparing the cargo tanks ready to carry the next LNG cargo, they must be dried out to avoid the formation of ice when the cargo tanks are cooled down.

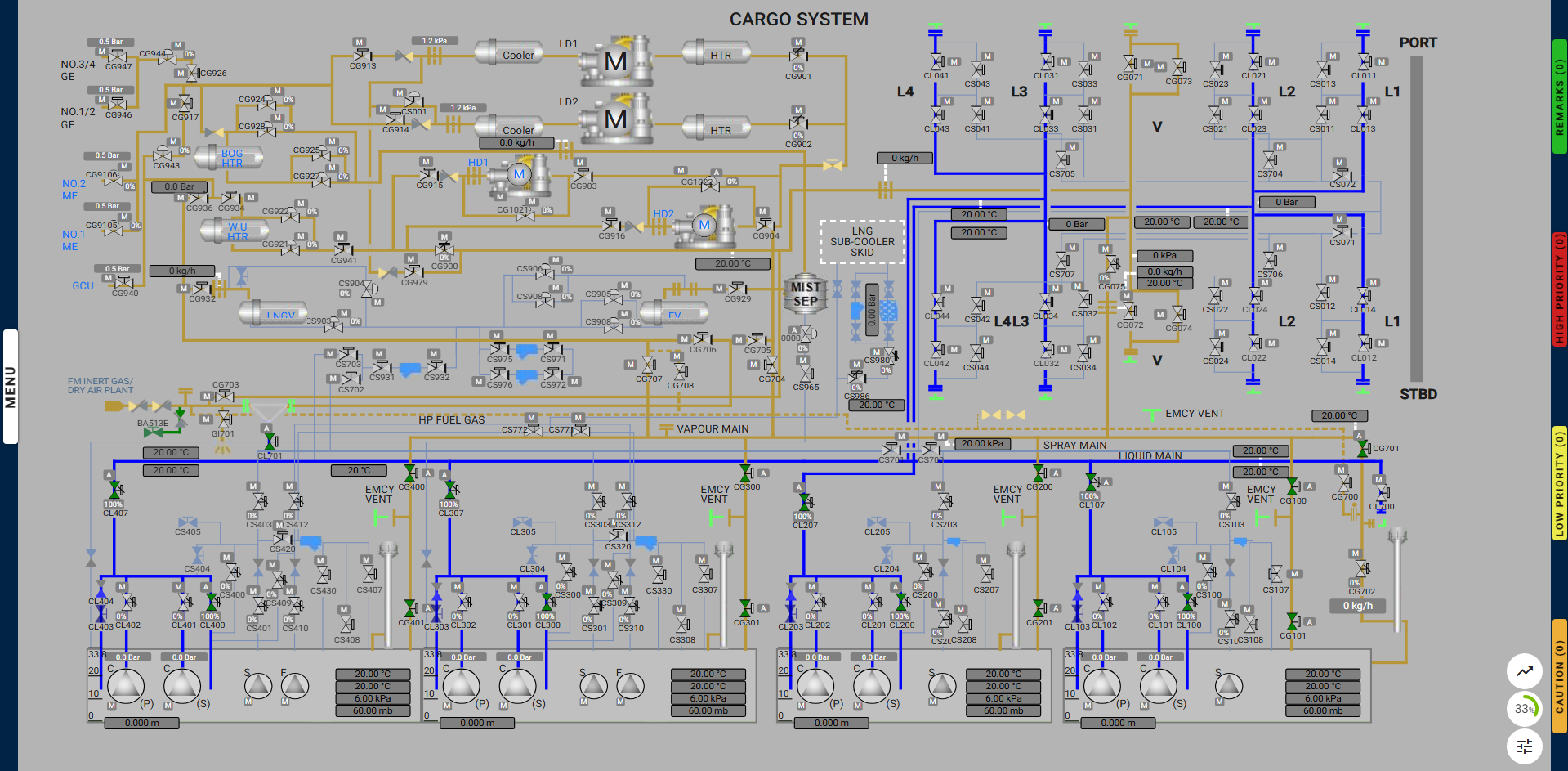

Dry-air, which is supplied by the inert gas generator in dry-air mode, is used to expel the moist cargo tank atmosphere via the displacement method of exchange, known as a ‘piston effect’. This can be achieved by introducing the dry air to the bottom of the cargo tank via the filling lines and venting at the top via the vapour lines and slowly displacing the cargo tank’s humid air with dry air. Alternatively, the dry air can be introduced at the top of the cargo tank via the vapour lines and expelled out of the bottom via the filling lines.

To decide upon which method to adopt depends upon the relative humidity of the cargo tank atmosphere, which will vary due to seasonal variations of humidity associated with the climate and location. However, it is assumed that in the summer months, the relative humidity is high, and in ‘Winter’ months, the relative humidity is low and thus dry.

Therefore, for summer months the dry air is introduced to the cargo tank bottom and the lighter warm humid air can be vented at the top of the cargo tank, whereas in winter months, the dry air is introduced at the top of the cargo tank and vented at the bottom.

The actual dew point should be measured to assess the relative humidity and thus the best method to achieve effective cargo tank atmosphere air exchange.

This exercise is designed to help users understand the procedures required to introduce dry air into cargo tanks using an inert gas generator, with the goal of achieving tanks with zero moisture. The process involves introducing dry air with a low dew point into the tanks to replace the moist air inside.

Key Objectives:

Exercise Breakdown:

This exercise provides hands-on experience in operating the inert gas generator, monitoring the tank atmosphere, and ensuring successful moisture removal to maintain safe conditions within the cargo tanks.

Milestones:

Alarms & Remarks:

| Alarm Condition | Alarm Time | Alarm Level | Alarm Title | Alarm Description | Action |

| Supply Started | Remark | Drying Of Cargo Tanks Started | Drying of the cargo tanks has started. | ||

| On Drying completed | Remark | Drying of tanks completed | Drying of cargo tanks is completed, stop the deivery of inert gas. | ||

| started delivery of Dry Air | Remark | Open Valve CG702 | Open the valve CG702, To vent out the Normal air. | ||

| Stopped delivery of Dry Air | Remark | Close Valve CG702 | Drying of tanks is stopped, close the valve CG702. | ||

| started delivery of Dry Air | Remark | Maintain IGG Oulet Flow And Outlet Flow To Atmosphere | Maintain IGG outlet flow and outlet flow to atmosphere between 15500 kg/h to 16500 kg/h. | ||

| when un necessary valve opened or required valve closed | Caution | Deviation Detected | Deviation from the exercise is detected, undo your last action. | Fails if that valve is not closed or opened within 1 minute |

Step By Step Procedure:

Gas Properties Display on the Detector:

Milestones:

Alarms & Remarks:

| Alarm Condition | Alarm Time | Alarm Level | Alarm Title | Alarm Description | Action |

| Supply Started | Remark | Drying Of Cargo Tanks Started | Drying of the cargo tanks has started. | ||

| On Drying completed | Remark | Drying of tanks completed | Drying of cargo tanks is completed, stop the deivery of inert gas. | ||

| started delivery of Dry Air | Remark | Open Valve CG702 | Open the valve CG702, To vent out the Normal air. | ||

| Stopped delivery of Dry Air | Remark | Close Valve CG702 | Drying of tanks is stopped, close the valve CG702. | ||

| started delivery of Dry Air | Remark | Maintain IGG Oulet Flow And Outlet Flow To Atmosphere | Maintain IGG outlet flow and outlet flow to atmosphere between 15500 kg/h to 16500 kg/h. | ||

| when un necessary valve opened or required valve closed | Caution | Deviation Detected | Deviation from the exercise is detected, undo your last action. | Fails if that valve is not closed or opened within 1 minute |

Step By Step Procedure:

Gas Properties Display on the Detector:

Proper Line Up For Drying: