The Discharging with Heel operation is carried out onboard an LNG carrier when the vessel arrives at the discharge port. The goal of this operation is to discharge the required amount of LNG using the cargo pumps and systems, while leaving a small amount of LNG (the “heel”) in the tanks for safety and operational purposes. This exercise is the first part of the discharging operation, where the user starts the discharging process and ensures a staggered discharge between different tanks.

The purpose of unloading with vapour return is to be able to empty the cargo tanks of LNG and replace this with cold LNG vapour returned from the terminal. The rate of discharge of LNG is balanced with the returning LNG vapour, keeping the vessel’s cargo tank within the pressure limits.

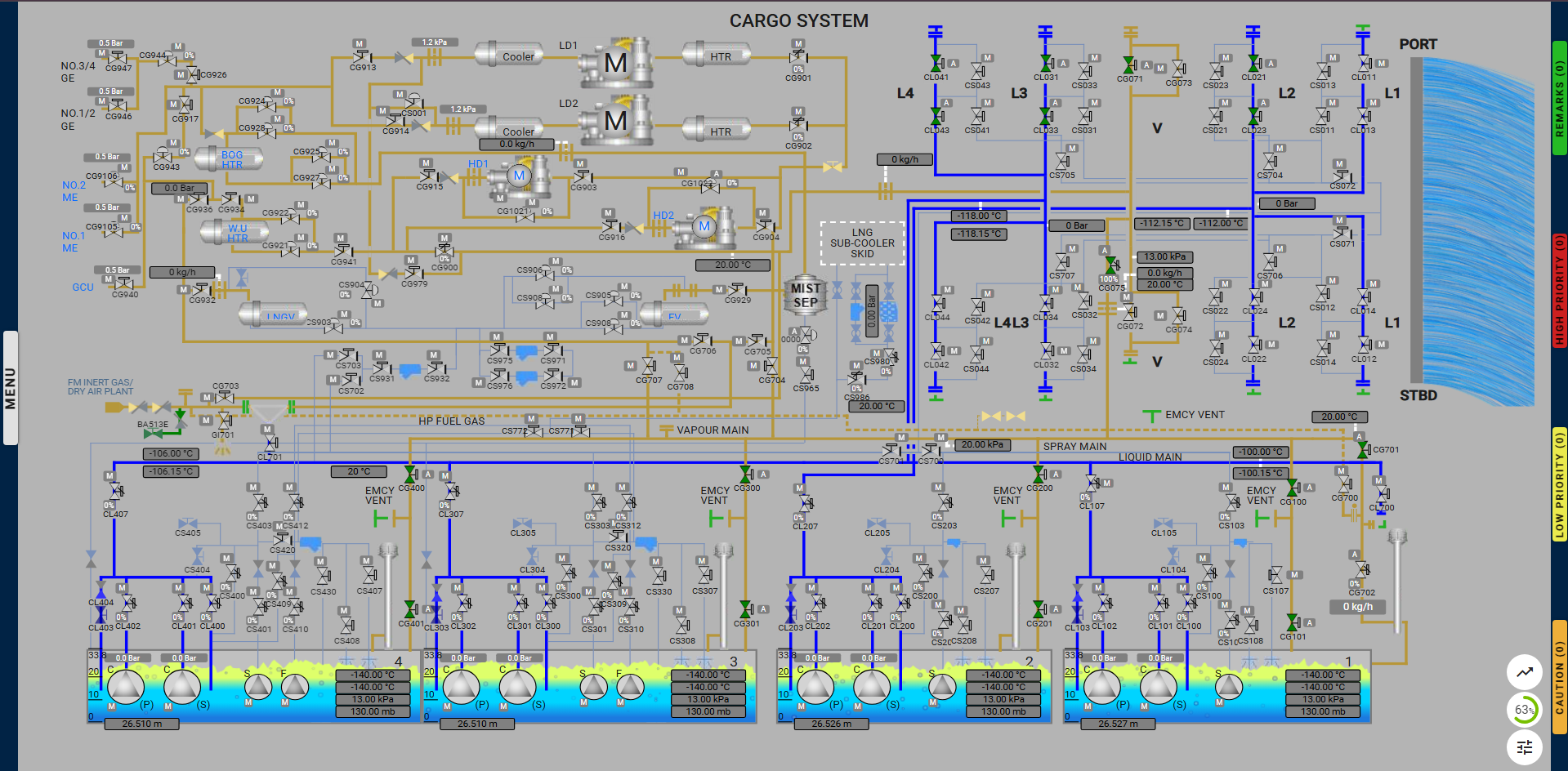

All cargo tanks are simultaneously unloaded using all the cargo pumps into the common liquid line and to the manifolds. It is usual for most terminals to have only three liquid lines and one vapour line connected.

The operation of the cargo pumps can be conducted from the IAS where the operator can select either manual control or auto control.

In manual control, the operator sets the valves to set values before starting each cargo pump. In auto control, the operator sets the valves to auto mode and each cargo pump will start in an auto sequence, when activated by the operator. All the interlocks must be clear to enable the cargo pump to start.

The final stop levels in all tanks should be pre-calculated to determine the amount of heel to be retained. In any event, the cargo pumps can be used to take out most of the LNG without needing to use the stripping/spray pumps.

To avoid unnecessary warming of the pump tower upper section, nozzles are fitted in the cargo pump discharge lines which will spray LNG to continue cooling the upper structure whenever the cargo pumps are running.

Precautions during discharging

The fixed gas detection system must be in operation during discharge;

When planning an LNG (Liquefied Natural Gas) discharging operation some potential learning objectives for a training program focused on the discharge of LNG (liquefied natural gas):

Note: When the HD compressor is reset, the surge valve will open, which may result in an incomplete lineup.

| Alarm Condition | Alarm Time | Alarm Level | Alarm Title | Alarm Description | Actions |

| Remark | Obtained Level Difference Between CT1 and CT2 | Obtained a 20 cm difference between CT1 and CT2. Now, the level difference can range between 35 and 45 cm. | |||

| Remark | Obtained Level Difference Between CT2 and CT3 | Obtained a 20 cm difference between CT2 and CT3. Now, the level difference can range between 15 and 25 cm. | |||

| Remark | Obtained Level Difference Between CT4 and CT3 | Obtained a 1.2 m difference between CT4 and CT3. Now, the level difference can range between 1.15 and 1.25m. | |||

| caution | In-proper Line Up For Discharging | Proper line-up has to be done for discharging LNG to the shore. | |||

| caution | Open Master Valve And Close Return | Open master valve CL107/207/307/407 and close return valve CL100/200/300/400 in CT1/2/3/4. | |||

| caution | Update CTS Report And Setup | CTS Report and setup have to be updated before discharging LNG to the shore. | |||

| remark | Started Unloading | Unloading of LNG has started, open master valves of remaining tanks and increase the discharge rate to the required level. | |||

| caution | Increase Flow Rate | Maintain flow rate between -11500 and -12500. | |||

| low | High Cross Over Pressure | High cross-over pressure in liquid line. | |||

| caution | Liquid Entering The Tank | Liquid entering, close master and return valves when pumps are not running. | |||

| caution | Deviation Detected | Deviation from the exercise is detected, undo your last action. |

Step By Step Procedure

Navigate to the ESD System page and follow these steps:

Ensure the correct lights and indications are on, confirming the ESD system is ready.

Cargo pumps require at least three active generators.

To prepare the generators:

b) Set Vapour Line to No.1 Vent Mast:

c) Set Vapour Manifold Valves:

d) Set Cargo Tank Vapour Valves:

Ensure all valves are set to the correct positions for proper line-up. These valves can be opened from different pages in the system.

(Note: Valve CG702 is only available in the Cargo System page.)

Important Note: When the HD compressor is reset, the surge valve will open, which may result in an incomplete lineup.

After 55 minutes of unloading, the user will be alerted to increase and maintain the flowrate between 11,500 m³/h and 12,500 m³/h.

Achieve the required tank level differences:

To achieve this, the user must adjust the pump discharge valves while monitoring the crossover pressure. If the crossover pressure is not maintained within the acceptable range, the exercise will be terminated.

Once the required tank differences are achieved, the exercise is completed.