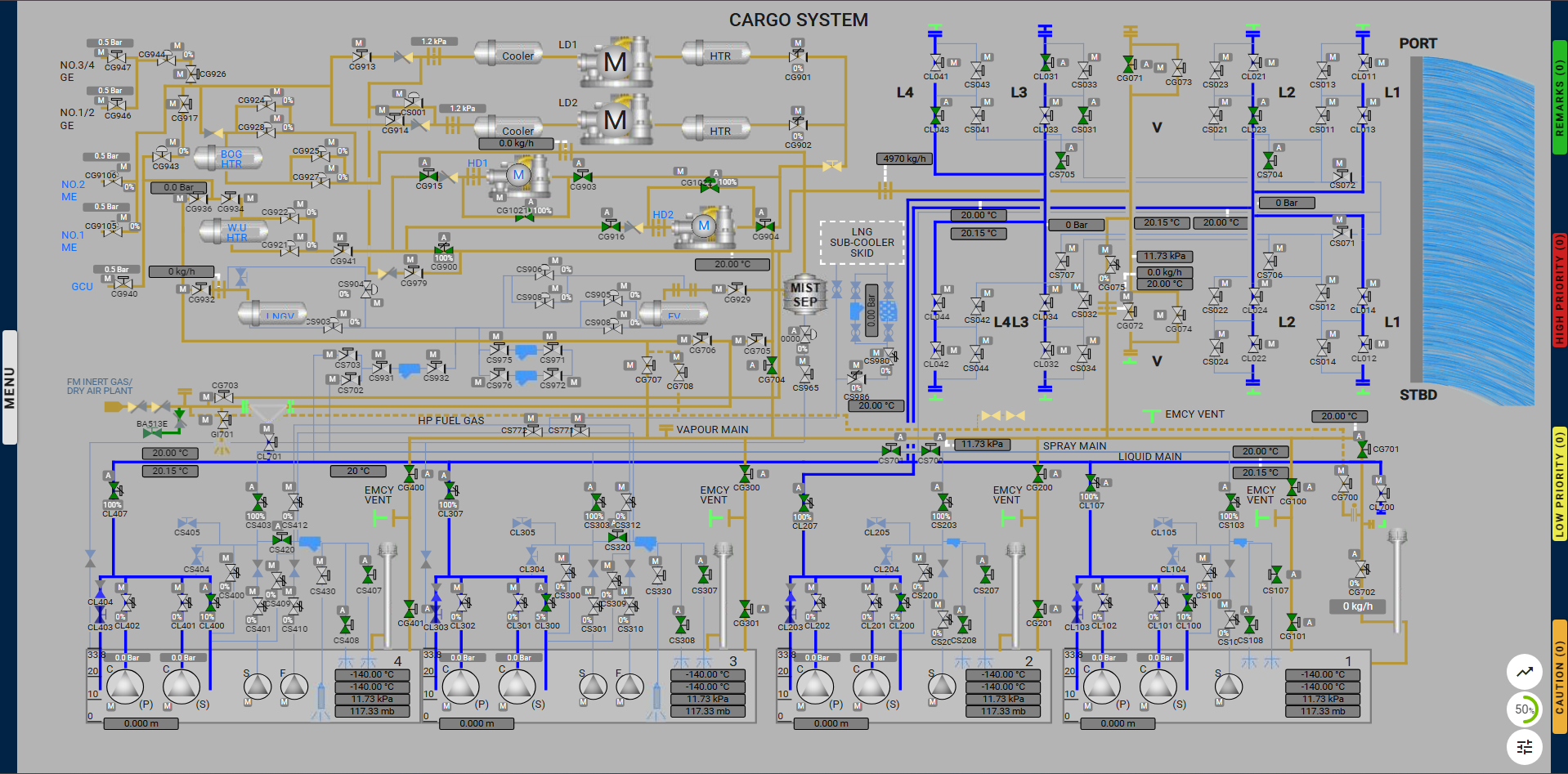

This operation is carried out onboard an LNG carrier after the cargo tanks have been successfully cooled to the required -130°C. During this operation, liquid LNG is supplied from the shore and directed from the spray lines to the main cargo line (liquid header). The objective is to achieve the required temperature of -100°C in the liquid lines so that the loading operation can commence.

The purpose of cooling down cargo lines is to avoid thermal shock on the piping and associated valves which would occur if no gradual cooling was employed. Therefore, prior to loading LNG into the cargo tanks, the cargo liquid lines, crossovers and cargo filling lines must be cooled down to cryogenic temperatures and this can be undertaken with LNG supplied from the vessel’s cargo tanks.

Learning Objectives for the Exercise

Participants will be able to effectively demonstrate the process of cooling down cargo lines on LNG ships, understanding the necessary safety protocols, operational procedures, and the importance of achieving the correct temperatures for safe LNG transfer.

Key Components:

Understanding Cooling Down:

Explain the purpose of cooling down cargo lines to prevent thermal shock during LNG transfer and ensure the integrity of the system.

Identify the significance of reaching appropriate temperatures to facilitate safe and efficient LNG loading.

Operational Procedures:

Detail the step-by-step process for cooling down cargo lines, including:

Explain the importance of managing flow rates to prevent rapid cooling.

Monitoring and Verification:

Practical Demonstration:

Assessment Criteria:

By achieving this objective, participants will gain the knowledge and skills necessary for safely and efficiently cooling down cargo lines on LNG ships, ensuring operational readiness for LNG transfer.

|

Alarm Condition |

Alarm Time | Alarm Level | Alarm Title | Alarm Description |

|

No Conditions |

3rd minute of the exercise | Caution | Close tank filling valves |

Close the filling valves CL200, CL300 and CL400. |

|

Cross Over Pressure > 4 bar |

whenever pressure reaches 4 bar | Caution | High Cross Over Pressure |

High cross over pressure in liquid lines, open filling valve CL400. |

|

After Opening CL400 to reduce cross over pressure |

20 Sec, After Opening the CL400. | Caution | Liquid entering the tank |

Liquid entering the tank, close the filling valves of all the tanks to required percentage. |

|

No Conditions |

12th minute of the exercise | Caution | Open filling valves |

Keep the filling valves CL100 and CL400 open. |

|

When temperature reaches -106°C in liquid header aft temperature. |

Approximately 15th minute of the exercise | Remark | Obtained required temperature in liquid header |

Obtained required temperature in liquid header for loading,Open CL033 and close spray line valve CS031. |

|

Deviation from the exercise |

whenever a deviation is detected. | Caution | Deviation Detected |

Deviation from the exercise is detected, undo your last action. |

Step by step procedure: