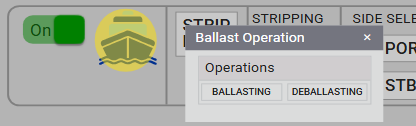

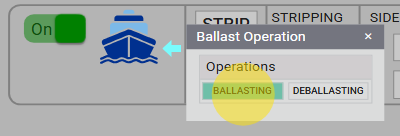

This exercise focuses on the important operation of ballasting cargo tanks, which is typically carried out simultaneously with the discharging operation. According to the latest regulations, ballast water must be treated before being transferred into the ballast tanks. Therefore, this exercise involves using the Ballast Water Treatment System (BWTS) and understanding the procedure to make it operational.

The primary goal of this exercise is for the user to understand the potential challenges and issues that can arise when operating the ballast water treatment system. Additionally, users will learn the correct setup procedures for the BWTS.

Learning Objective for Ballasting Operation on an LNG Carrier using BWTS:

By the end of this exercise, participants should be able to:

This exercise will help participants develop the necessary skills to efficiently perform ballasting operations using BWTS, with an emphasis on safety, environmental responsibility, and regulatory compliance.

After starting or resuming the ballasting, the user should not open any non-required valves or close any required valves. If this happens, a caution message will appear, instructing the user to undo the previous action. If the user fails to correct the action, the exercise will be terminated.

After starting or resuming the ballasting operation, the user must maintain the list and trim angle below 1.5°. If the angle exceeds 1.5°, a low-priority message will be displayed, instructing the user to reduce the angle. If the angle is not corrected, the message will escalate to a high-priority alarm, and the exercise will be terminated within 5 minutes unless the angle is brought back below 1.5°.

| Alarm Condition | Alarm Time | Alarm Level | Alarm Title | Alarm Description | Action |

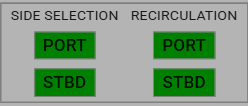

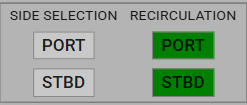

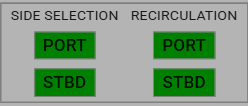

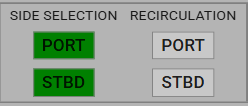

| caution | Open Required Tank Valves | Open required tank filling valves and run the system in recirculation before selecting the side mode. | |||

| remark | Ballasting Of Tanks Started | Maintain initial flow at 1000 m³/h. | |||

| remark | Increase The Flowrate | Increase and maintain flowrate at 2500 to 3000 m³/h. | |||

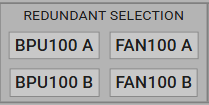

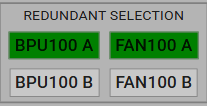

| remark | Booster Pump Abnormal | The BPU 100A Booster Pump is abnormal. Reset the BPU 100A pump and select the BPU 100B pump after acknowledging the alarm in BWTS panel. | Reset the current BPU And Start the other After Acknowledging the alarm in BWTS Panel. | ||

| remark | Booster Pump Abnormal | The BPU 100B Booster Pump is abnormal. Reset the BPU 100B pump and select the BPU 100A pump after acknowledging the alarm in BWTS panel. | Reset the current BPU And Start the other After Acknowledging the alarm in BWTS Panel. | ||

| remark | Low Water In TRO-100 | There is no water in TRO 100 sensor, override the highlighted valve and reduce the valve opening to at least 40%. | Acknowledge the alarm in BWTS Panel and reduce the highlighted valve | ||

| remark | Low Water In TRO-101 | There is no water in TRO 101 sensor, override the highlighted valve and reduce the valve opening to at least 40%. | Acknowledge the alarm in BWTS Panel and reduce the highlighted valve | ||

| remark | Low Injection Pressure Water In TRO-100 | Increase the valve opening of the highlighted valve to increase the pressure. | Acknowledge the alarm in BWTS Panel and Adjust the highlighted valve | ||

| remark | Low Injection Pressure Water In TRO-101 | Increase the valve opening of the highlighted valve to increase the pressure. | Acknowledge the alarm in BWTS Panel and Adjust the highlighted valve | ||

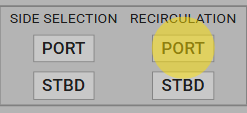

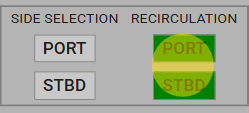

| remark | Filter SF-100 Abnormal | Filter Unit SF-100 Abnormal. Run port side in recirculation mode and reset the filter pump. | Acknowledge the alarm in BWTS Panel and return the side to recirculation | ||

| remark | Filter SF-101 Abnormal | Filter Unit SF-101 Abnormal. Run starboard side in recirculation mode and reset the filter pump. | Acknowledge the alarm in BWTS Panel and return the side to recirculation | ||

| caution | Deviation Detected | Deviation from the exercise is detected, undo your last action. | |||

| Low priority

|

High Trim Difference between port and stbd

|

High trim differences adjust tank filling valves accordingly. |

Step By Step Procedure

During the ballasting operation, we will be filling tanks 2(P), 2(S), 4(P), and 4(S).

Open the following tank filling valves:

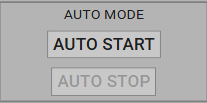

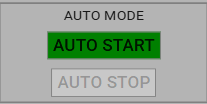

After successfully running the system in recirculation:

During the first 3 minutes, maintain a low flow of 1000 m³/h.

After 3 minutes, you will receive an alert to increase the pump flow rate.