The inerting of cargo tanks is carried out once the LNG vapor inside the tanks has been warmed up. The process involves replacing the LNG vapor with inert gas, preparing the vessel for the upcoming dry dock. The primary goal is to remove the flammable LNG vapor from the tanks and make them safe for entry and inspection.

The exercise uses the inert gas generator onboard both vessels. The inert gas, being heavier, is introduced into the tanks from the bottom, while the lighter LNG vapor is extracted from the top. This process is known as the displacement of LNG vapor with inert gas.

Participants will be able to effectively demonstrate the process of inerting cargo tanks on LNG ships using inert gas, understanding safety protocols, operational procedures, and the importance of preventing explosive atmospheres.

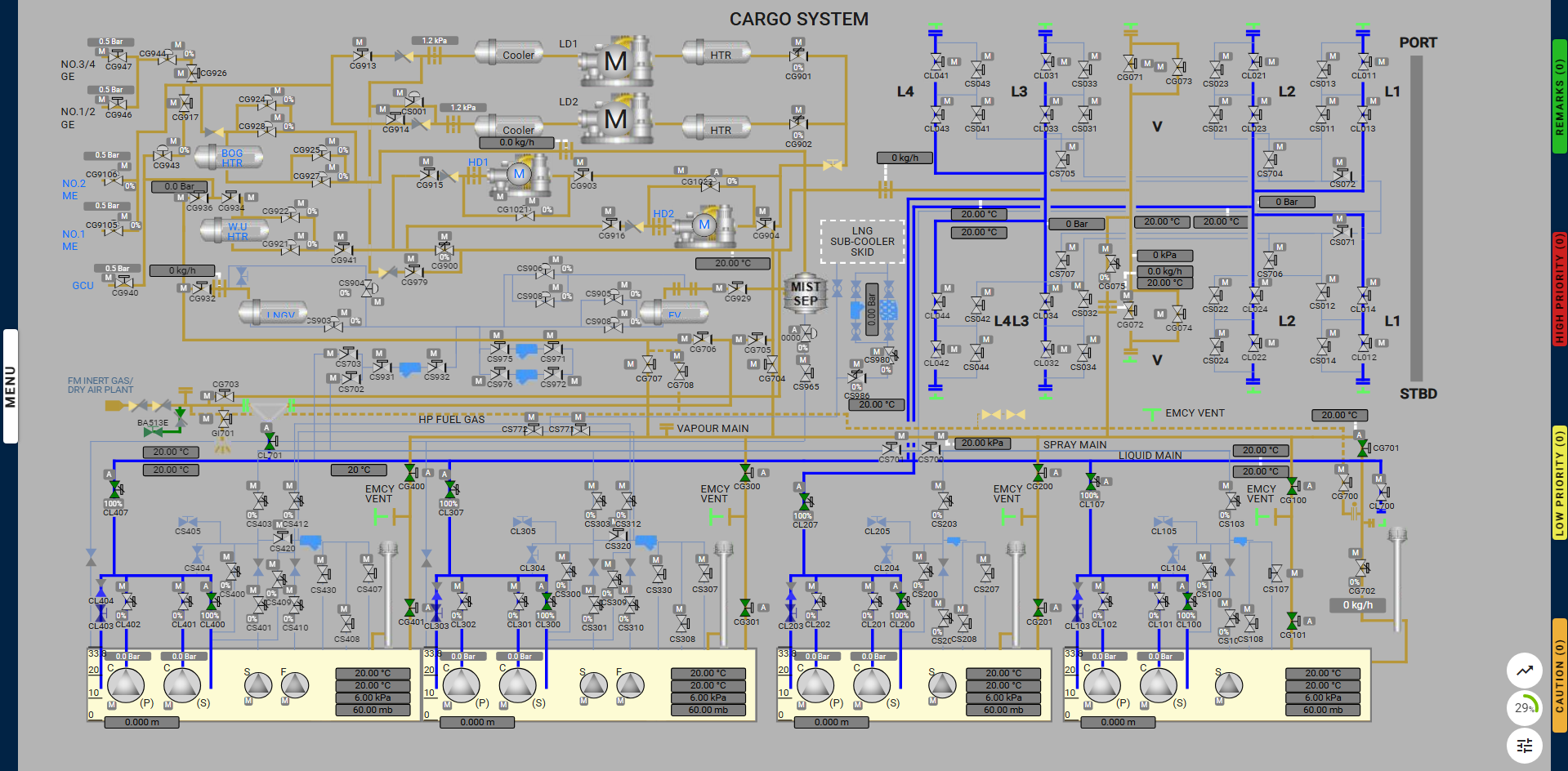

Key Components:

Assessment Criteria:

By achieving this objective, participants will gain the necessary knowledge and skills to safely and efficiently inert cargo tanks on LNG ships, enhancing overall safety and operational integrity.

Milestones:

Actions During Exercise:

Alarms & Remarks

| Alarm Condition | Alarm Time | Alarm Level | Alarm Title | Alarm Description | Action |

| remark | Inerting Of Cargo Tanks Started | Inerting of the cargo tanks has started. | |||

| remark | Inerting Of Tanks Completed | Inerting of cargo tanks is completed, stop the delivery of inert gas. | |||

| remark | Check The Sampling Point On Vapour Line | Check the sampling point on vapour line for dry air properties, in all cargo tanks. | |||

| remark | Close Valve CG702 | Inerting of tanks is stopped, close the valve CG702. | |||

| remark | Open Valve CG702 | Open the valve CG702 to vent out the warm vapour. | |||

| caution | Maintain IGG Outlet Flow And Outlet Flow To Atmosphere | Maintain IGG outlet flow and outlet flow to atmosphere between 15,500 kg/h to 16,500 kg/h. | |||

| caution | Deviation Detected | Deviation from the exercise is detected, undo your last action. |

Step By Step Procedure

1. Start The Portable Multi Gas Detector And Dew Point Meter

Steps:

2. Install The Spool Piece

3. Set Cargo Tank Vapour Valves

|

Valve |

Status |

|

CG100 |

Open |

|

CG101 |

Open |

|

CG200 |

Open |

|

CG201 |

Open |

|

CG300 |

Open |

|

CG301 |

Open |

|

CG400 |

Open |

|

CG401 |

Open |

Once these valves are set, the milestone is complete.

4. Set Cargo Tank Liquid Valves

|

Valve |

Status |

|

CL100 |

100% |

|

CL107 |

100% |

|

CL200 |

100% |

|

CL207 |

100% |

|

CL300 |

100% |

|

CL307 |

100% |

|

CL400 |

100% |

|

CL407 |

100% |

5. Set Vapour Line To No. 1 Vent Mast Regulating Valve

|

Valve |

Status |

|

CG701 |

Open |

6. Set Inert Gas Line Valve

|

Valve |

Status |

|

CL701 |

Open |

7. Prepare And Start Ballast Pump 2

Steps:

8. Prepare Inert Gas Generator In Inert Gas Mode

Steps:

9. Start Inert Gas Generator In Inert Gas Mode

Steps:

10. Cargo Tank Dew Point < -40°C

11. Cargo Tank Methane Content < 2%

12. Maintain Cargo Tanks Pressure Between 5 kPa And 7 kPa

13. Check Sampling Points

14. Stop Inert Gas Supply