The warming up of cargo tanks is performed in preparation for an upcoming dry dock. This operation is carried out after the tanks have been emptied using the spray pumps. The primary objective is to make the tanks free of liquid and to warm the LNG vapor inside the tanks.

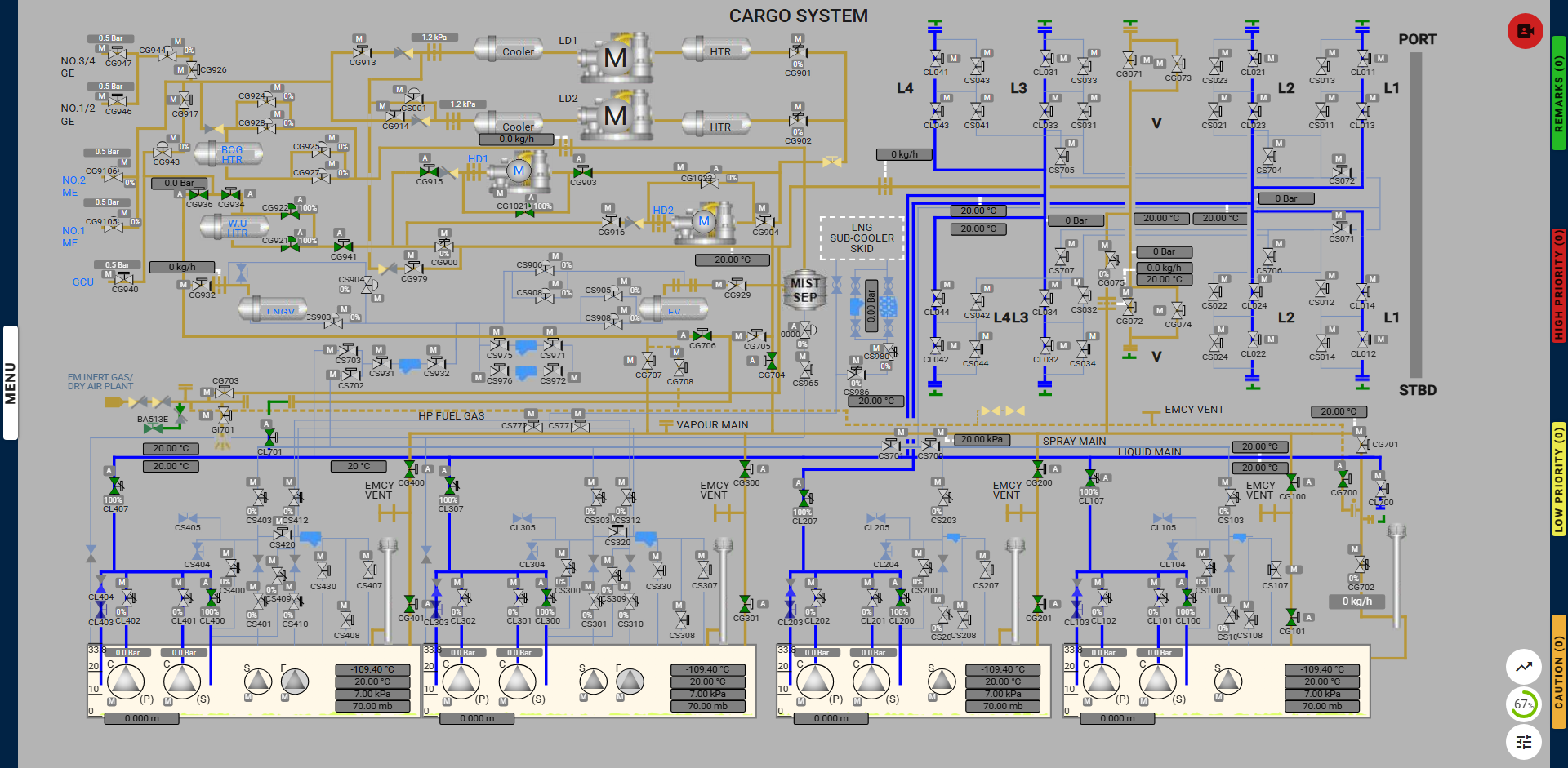

The process is conducted using the high-duty compressor (HD compressor) onboard. The vapor is pushed from the HD compressor to the LNG heater, where the temperature increases. The warmed vapor is then reintroduced into the cargo tank from the bottom, ensuring that any remaining liquid also evaporates.

Participants will be able to effectively demonstrate the process of warming up cargo tanks on

LNG ships to achieve a liquid-free state, understanding the necessary safety protocols,

operational procedures, and the importance of maintaining safe conditions during this

process.

By achieving this objective, participants will gain the knowledge and skills necessary for safely and efficiently warming up cargo tanks on LNG ships, ensuring they are liquid-free and ready for subsequent operations.

Exercise Milestones:

Actions During the Exercise:

Deviation from Exercise:

Not Maintaining HD Compressor Flow:

Not Opening the Warm-Up Heater Bypass Valve:

Alarms & Remarks

| Alarm Condition | Alarm Time | Alarm Level | Alarm Title | Alarm Description |

| remark | Preparing Of Warm Up Heater | Generally, the Warm-up heater is kept ready few hours prior to the operation. | ||

| remark | Open Warm Up Heater Drain Bypass Valve | Open the Warm Up Heater Drain Bypass valve immediately. | ||

| remark | Valve CG922 To Auto Mode | Set the valve output set value to 40 and change the valve to auto mode. | ||

| remark | Reduce Warm Up Heater Vapour Outlet Temperature | Adjust the valve CG 922 to reduce the WU heater Vapour outlet temperature to 40°C | ||

| caution | Maintain Warm Up Heater Flow | Adjust the HD compressor Veins and maintain the warm-up heater outlet flow between 11,500 kg/h to 12,500 kg/h. | ||

| remark | Run HD Compressor At 0 Veins | Run HD Compressor at 0 veins for the first 5 minutes. | ||

| caution | High Pressure Inside Cargo Tanks | Start the LD Compressor to reduce the pressure. | ||

| caution | High Pressure Inside Cargo Tanks | Start another LD Compressor to reduce the pressure. | ||

| caution | High Pressure Inside Cargo Tanks | Start GCU to reduce the pressure. | ||

| caution | Deviation Detected | Deviation from the exercise is detected, undo your last action. |

Step By Step Procedure

| Valve | Action |

| CG100 | Open |

| CG101 | Open |

| CG200 | Open |

| CG201 | Open |

| CG300 | Open |

| CG301 | Open |

| CG400 | Open |

| CG401 | Open |

| Valve | Action |

| CL100 | Open |

| CL107 | Open |

| CL200 | Open |

| CL207 | Open |

| CL300 | Open |

| CL307 | Open |

| CL400 | Open |

| CL407 | Open |

| Valve | Action |

| CG704 | Open |

| CG903 | Open |

| CG1021 | Open |

| CG915 | Open |

| Valve | Action |

| CL701 | Open |

| CG706 | Open |

| Valve | Action |

| CG941 | Open |

| CG921 | Open |

| CG922 | Open |

| CG934 | Open |

| CG936 | Open |

| Valve | Action |

| CG700 | Open |

| CG702 | Closed & Auto |

Note: The opening percentage of CG702 ranges from 0% to 100%, corresponding to a vapour outlet flow of 0 to 20,000 kg/h.